The primary function of the drill collars is to provide sufficient WOB (Weight on bit). The weight of the collars also ensures that the drill pipe is kept in tension to prevent buckling.

Drill collars are heavy, stiff steel tubulars. They are used at the bottom of a BHA to provide weight on bit and rigidity.

Flush or spiral drill collars are available.

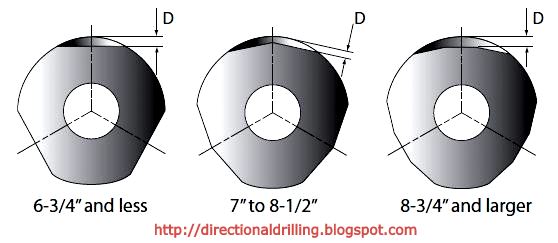

In directional drilling, spiral drill collars are preferable. The spiral grooves machined in the collar reduce the wall contact area by 40% for a reduction in weight of only 4%, thus reducing the chances of differential sticking.

The Spiral drill collars usually have slip and elevator recesses. Stress-relief groove pins and bore back boxes are optional.

SHORT DRILL COLLARS

Short Drill Collars (SDC's) are also called a pony collar.

It is simply a shortened version of a steel drill collar.

Short drill collars may be manufactured or a steel drill collar may be cut to make two or more short collars.

For a Directional Driller, the SDC and the short non-magnetic drill collar (SNMDC) have their widest application in the make-up of locked BHAs. SDCs of various lengths (e.g. 5’, 10’, 15’) are normally provided by the DD company.

NON-MAGNETIC DRILL COLLARS (NMDC)

Non-magnetic drill collars are usually flush (non-spiral).

They are manufactured from high-quality, corrosion-resistant, austenitic stainless steel.

Magnetic survey instruments (MWD / Magnetic Single Shots / Multi Shots) run in the hole need to be located in a non-magnetic drill collar of sufficient length to allow the measurement of the earth’s magnetic field without magnetic interference.

Survey instruments are isolated from magnetic disturbance caused by steel components in the BHA and drillpipe.

SHORT NON-MAGNETIC DRILL COLLARS (SNMDC)

SNMDC is a short version of the NMDC.

They are often made by cutting a full-length NMDC.

The SNMDC may be used between a mud motor and an MWD collar to counteract magnetic interference from below.

It is also used in locked BHAs, particularly where the borehole's inclination and direction give rise to high magnetic interference.

Finally, BHAs for horizontal wells often use a SNMDC.

The amount of bending a drill collar can undergo will depend on the material and the dimensions of the collar.

The stiffness of the collar is the product of the collar's moment of inertia (I) and the modulus of elasticity for that material (E).

The moment of inertia (I) for a hollow cylindrical pipe is given by :

I = Π (D4 – d4) / 64

Where :

I = Moment of Inertia (in inch4)

D = Outside diameter (in inches)

d = Inside diameter (in inches)

The modulus of elasticity for various materials can be obtained from manufacturer's specifications.

E.g. for steel E = 29 X 106 psi; for aluminium E = 11 X 106 psi; for monel E = 26 X 106 psi.

Thus, an aluminium drill collar will be more flexible than a steel drill collar of similar dimensions.

IMAGES :

|

| Flush Drill Collar |

|

| Non-Magnetic Drill Collar |

|

| Non-Magnetic Drill Collars |

|

| Spiral Drill Collars |

|

| Used Spiral Drill Collars |

Drill Collar Manufacture Process

Figure below shows the cross sections of the drill collars and the reduced contact area with the wall of the hole.

Spiral Drill Collar Typical Size :

Note: Note: Loss of weight is approximately 4% compared to slick drill collars. Length of spiralled section allows reconditioning of connections.

Drill Collar Material Table :

Elevator and Slip Recess Specification :

BLOG ENDS

It is imperative that we read blog post very carefully. I am already done it and find that this post is really amazing.

ReplyDeleteמדביר מקצועי